Products

- Home

- Products

// New Equipment

CS75: the winch you wanted!

A wire rope winch with great performance that will enable you to always lift scenery, trussing, lights, banners and performers in a safe, reliable and discrete manner.

// Technical Specification

Here is why CS75 features the best technology on the market:

Previous

Next

FLEXIBLE

- Zero fleet rope lead-off system: the rope always remains in the same point in relation to the machine, no matter how much rope is wound on to the drum.

- The outfeed pulley pivots on ball bearings, which enables to correct any alignment errors and control off-axis rope movement of up to no less than 20 degrees.

- Rope outfeed on 4 sides for the utmost installation flexibility, for example above a truss bar or horizontally, in the event of a necessity to limit the vertical space occupied.

- Both vertical and horizontal installation and operation.

- Quick-lock hanging system on 4 sides with independent clamps, running on tracks and able to be positioned freely, with mounting slots adaptable to 30x30, 40x40 and 52x52 trussing without having to replace the hanging system.

- Accessories available for single-tube installation, horizontal installation and overhung installation.

EASY TO HANDLE

- Dimensions 84x29x55 cm.

- Weight 84 kg.

- 8 handles, 4 of which are fitted on the short sides to facilitate the winch’s mounting, and 4 on the long sides for handling operations.

- Suitable for installations with limited load capacity or in restricted spaces, in which off-the-shelf winches and hoists cannot be used for questions of weight and dimensions.

- Quick-lock hanging system on 4 sides with independent clamps, running on tracks and able to be positioned freely, with slots adaptable to 30x30, 40x40 and 52x52 trussing without having to replace the hanging system.

Previous

Next

SAFE

- Two independent super-silent brakes, one of which is mounted directly on the drum, fitted with a contactless “brake open” sensor, for the utmost safety and efficiency in the event of emergency braking.

- Double IP65 Encoder (absolute and incremental) for monitoring position and speed.

- Dynamic safety factors of over 10:1 for the rope and 6:1 for the rest of the components.

- Double limit switch system (end-of-travel and over-travel) which acts directly on the rope guide trolley.

- SIL3 load cell for monitoring applied weight and No-Load, no matter what the position of the machine and rope outfeed direction.

- Rope keeper roller on the drum, fitted with a safety sensor that intervenes in the event of the rope leaving its intended groove.

- Safety control system on the transmission belts, triggering an emergency stop in the event of excessive tension or breakage.

COMPLIANT

- Designed in compliance with the very recently approved standard UNI EN 17206:2020 “Machinery for Stages and Other Production Areas”.

- Compliant with Machinery Directive 2006/42/CE.

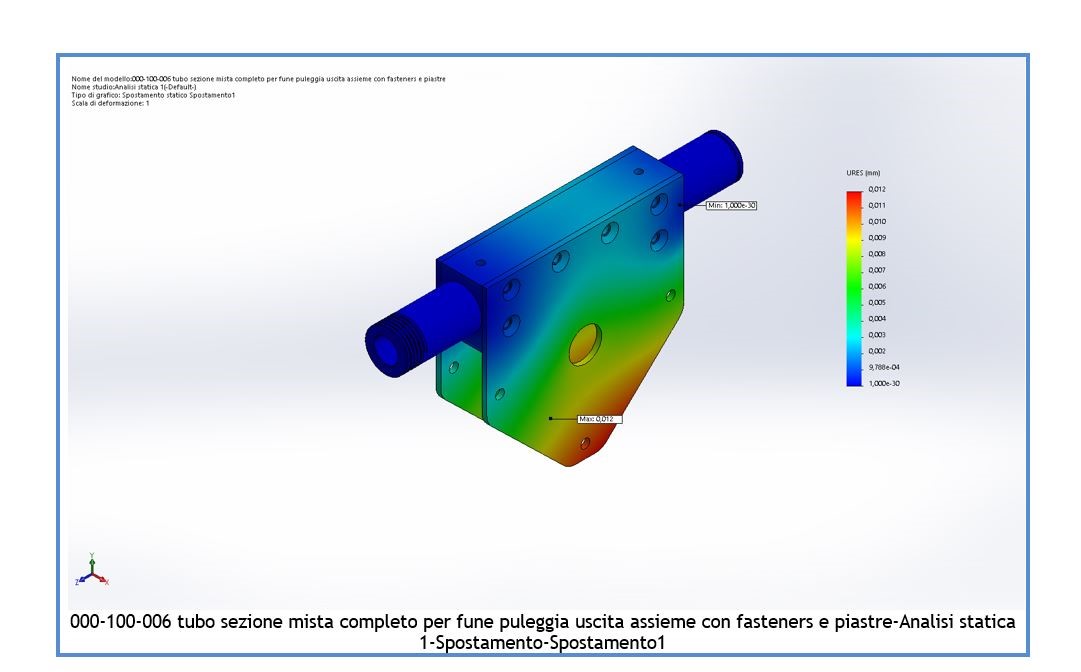

- Advanced Design and Simulation methods were used in order to optimize materials and components while also maintaining high safety and reliability standards.

RELIABLE

- Designed and certified for 1,600 hours’ operation with full load work at maximum speed.

- Constructed with quality component materials, to ensure minimum maintenance and low running costs.

INVISIBLE

- Total-black look

- Black wire rope

- Automatic rope line recovery system

INTERFACEABLE

- Ready for use with the most widespread show automation control systems.

- Large double contact box able to also hold any control system electronics as well as the terminal strip with all the contacts.

- The machine can also be supplied complete with a Movecat I-Motion control system. comando Movecat I-Motion.

- On request, Creative Systems can also provide a System Integration service.

SCALABLE

- Series CS winches can also be supplied in other versions with even higher technical specifications, such as, for example, greater working load, speed and acceleration.